Smart from

every angle

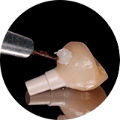

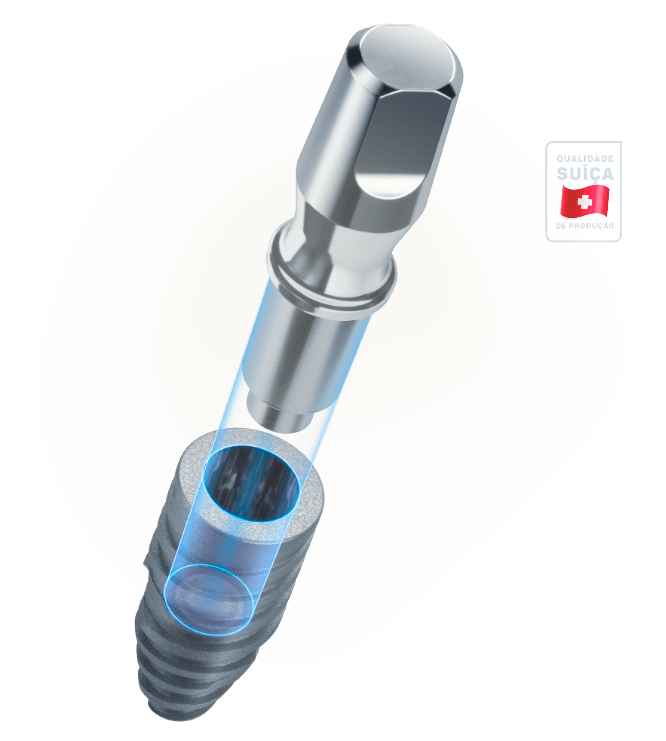

The incredible possibility of angulating the prosthetic component in your office

The Arcsys Implant System brings the exclusive technology of angulation of the prosthetic components in up to 20°, in your clinic or laboratory. Innovation that allows the best surgical and prosthetic planning. Check below how it is simple:

Main features

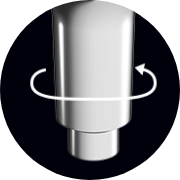

Customizable angle

Allows up to 20° angulation, achieving better aesthetic and functional results.

3 times more resistant

Manufactured from high-strength implantable special alloys, in accordance with ASTM F138 and ABNT NBR ISO 5832-1.

Security

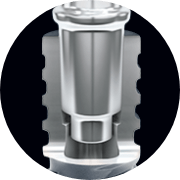

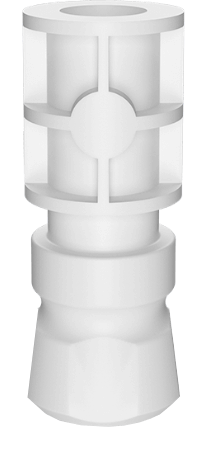

Frictional Morse Cone Interface

Versatility

Interchangeable components between different implant diameters.

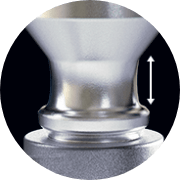

Diversity

Available in different heights to accommodate variations in mucosal thickness.

Possibilities

Screw-in, cemented, single or multiple prostheses

Active tip

Performs the function of a drill bit and stabilizes the drilling.

Installation safety

Cooling flow, for lower heat generation

Innovative geometry

Tool control throughout surgical preparation

Side channels

Through-bit irrigation and bone tissue collection capability

Material

TiN (titanium nitride) coating, providing increased surface hardness, lower friction, and greater durability.

Depth limiters

Enhanced drilling safety. Easy to handle, interchangeable and quick and precise fit.

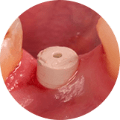

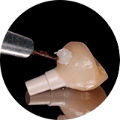

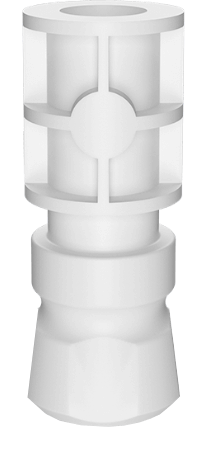

Multifunctional PEEK Component

PEEK: a high-performance, biocompatible polymer with unique properties that make it the ideal choice for today's most demanding applications. Considered one of the world's highest-performance engineering thermoplastics, with over 35 years of proven performance in demanding environments.

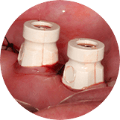

Multifunctional abutments

Peri-implant tissue former

Implant-supported temporary prosthesis abutment

Implant transfer

Multifunctional transfer

Prosthetic component transfer

Temporary denture support

Prosthetic component protector

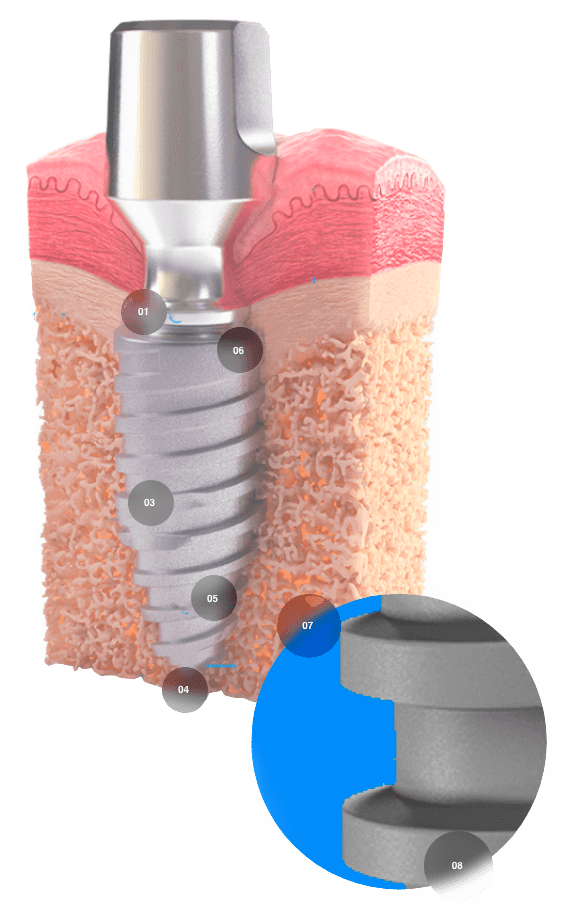

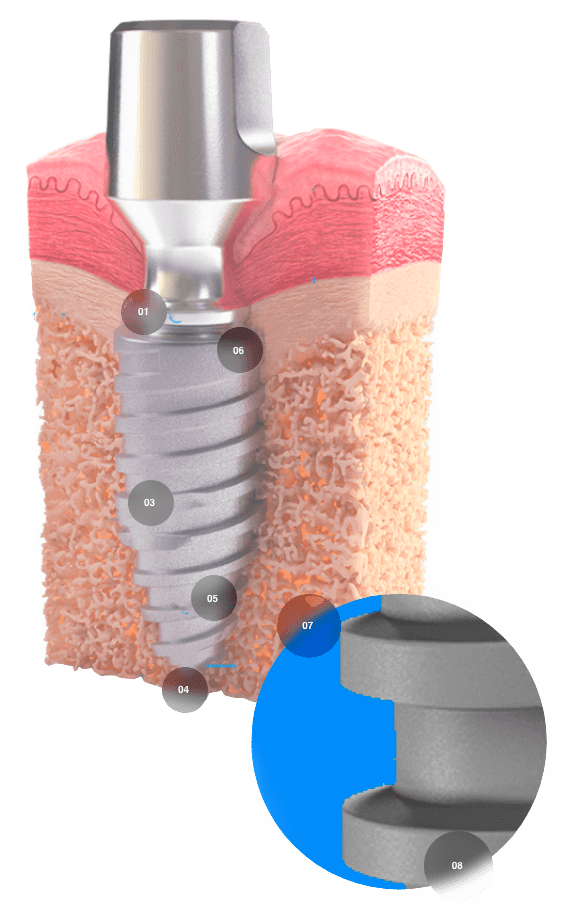

Implants with the best concepts

On macro and microgeometry

Unique prosthetic interface in all dimensions of the implant.

Titanium alloy (Ti6Al4V): best mechanical performance and total biocompatibility.

They promote bone compaction, resulting in greater primary stability.

Better screwability to the bone substrate.

Greater safety near noble structures, such as nerves or facial sinuses.

Platform Switching: guarantees peri-implant stability.³

They promote bone compaction, resulting in greater primary stability.

Excellent quality of surrounding bone tissue.

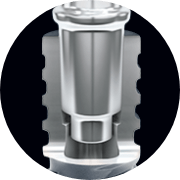

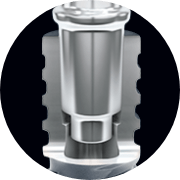

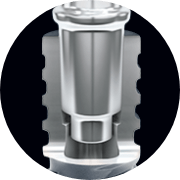

True Morse taper with manufacturing warranty

The Frictional Morse Cone is a commonly used connection system in mechanical engineering when it is necessary to join two bodies in a stable way, without the need for a screw.

- Screw-free: no loosening of the component/prosthesis;

- Greater biological seal: protection against bacterial infiltration;

- More aesthetic: favors the emergency profile;

- Gingival health: better accommodation of peri-implant tissues;

- Absence of micromovements: elimination of bad odor;

- Presents greater safety in the installation and removal (if necessary) of the prosthetic component.

In pure Morse cone systems, the pressure exerted to lock the intermediate in the implant generates sufficient frictional resistance for a safe connection. The non-use of the screw eliminates the problem of eventual loosening and favors the long-term performance of the system, unlike what happens with implants that have HE and HI platforms.

Quality Control

High-quality machinery

High-performance Swiss CNC lathes are used to manufacture the implants and components.

100% inspection of components

Every Arcsys Morse Cone is 100% inspected to ensure the effectiveness of its coupling.

High-precision measuring equipment

All Arcsys System components are inspected using high-tech 3D measurement equipment.

Highly qualified team

The team is trained and qualified in the production and quality control processes of the entire Arcsys line.

Scientific proof

Taxa de sucesso do Implante Arcsys de 98,2% e 0% de taxa de soltura

A recent study by UFSC found that Arcsys implants had a success rate of nearly 100% in both multiple and single-tooth restorations. Source: 1 Center for Dental Implant Education and Research. Federal University of Santa Catarina. Prof. Dr. Ricardo Magini and team. 2018.